How to design the best battery pack with the Power Battery calculator

Recently, we’ve added our battery calculator to our website. This is a very helpful tool, when you’re designing and building your own EV drivetrain. In this blog we’d like to take a closer look into how this tool can help you to pick the best batteries for your application, design your own battery pack, and save money in the process.

Get the characteristics of your motor and controller

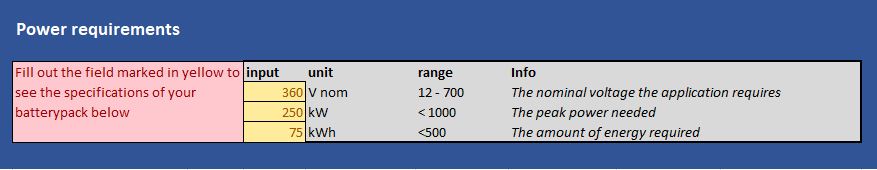

When you open our calculator, you’ll notice that there are three fields to enter values at the top of the sheet: nominal voltage (V nom), peak power (kW) and energy (kWh). The nominal voltage and peak power are defined by the motor and controller you’ve chosen for the drivetrain. The amount of energy you require is defined by the required range or number of operating hours of your application. Before you proceed, make sure you have these values determined in the use case(s) of the application you’re building.

To explain the next steps, we’ve decided to go with the values of 360 V nom, 250 kW and 75 kWh, which are roughly what you can expect when you’re building a high-end electric luxury car.

Check the results per type of battery

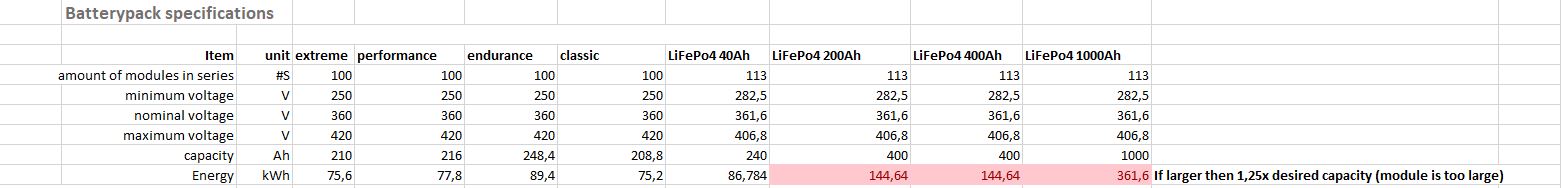

Every column in the results represents a different type of battery, with the first four (from left to right) being our own Li-ion Power Battery modules: Extreme, Performance, Endurance and Classic, with some LiFePo4 cells for comparison and to present a real alternative.

The first results you want to check are the rows containing the data for the voltages, capacity, and energy. For our example we see the following:

The red fields indicate that we do not recommend using this type of battery for your application. But, the Power Battery Extreme, Performance, and Endurance modules all look promising. Let’s take a closer look into these options.

Select batteries with an optimal operational range

Keep in mind that building a battery pack that often needs to operate at maximum power will be tough on the batteries. This will have a negative impact on the lifetime of the batteries. With the batteries being the most expensive part of your electrical drivetrain, we recommend designing your battery pack with a bit more energy and a higher maximum power than you’ll actually need for your motor and controller.

It is important to keep the voltage range of the battery pack within the voltage range of the controller. If your maximum battery pack voltage is too high, the controller will be overburdened and will break down more easily. Or, if your maximum battery pack voltage is too low, you need a bigger battery pack to compensate for the missing voltage with more cells in parallel. This is not only more expensive, but it runs the additional risk of generating too much heat in your system. That means you either have to slow down to reduce the heat in the motor, or the cooling system needs to be upgraded to deal with the additional heat that’s being generated.

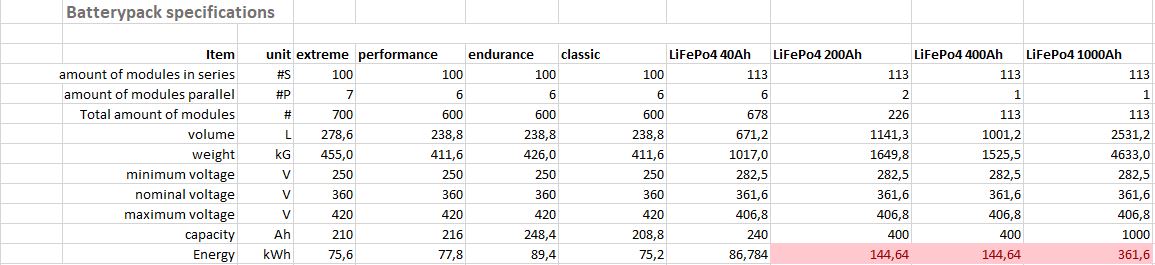

In our example, we’re still rooting for either our Extreme, Performance or Endurance batteries, with a slight preference for the last one, because it gives us more energy.

Costs and dimensions – time to make a choice

Finally, we need to take both costs (purchasing costs and lifetime) and the dimensions of the battery pack into consideration. Let’s take a look at our example again and make a decision.

As you can see, we’d need 100 modules more if we choose the Power Battery Extreme cells for our application. That is a lot of money! So, we decide not to use those. Additionally, the differences in weight and size between Performance and Endurance are negligible. We’d settle for the Performance type of batteries, which has enough room in the specs for our taste, but choosing the Endurance cells because of the additional energy this may give you, is equally valid.

Final thoughts, and learning more about battery packs

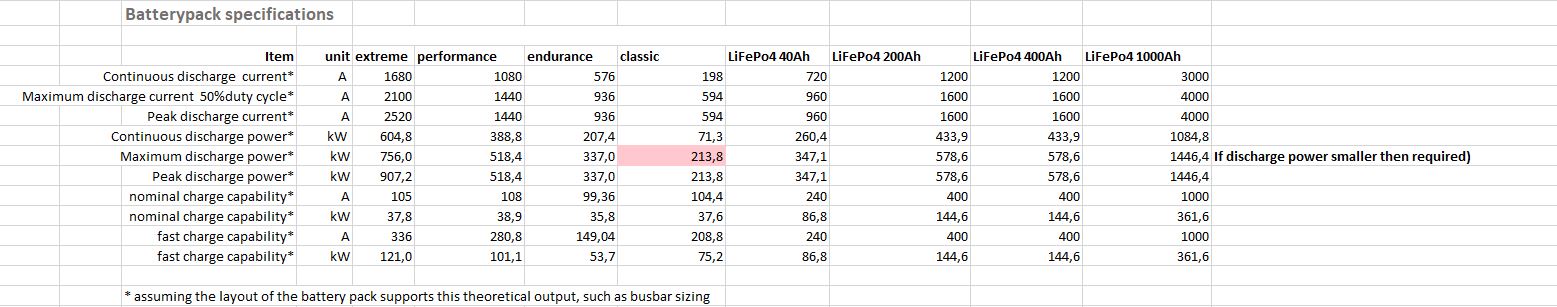

Our sheets contain additional data about the battery packs you’re assembling. Such as continuous and maximum discharge power, nominal and fast charge capability and more. Since we don’t know what you’re building, we don’t know how hard it might be to reach a charging station, or if you need to bring your own to a construction site, for instance. So, keep an eye on the additional requirements, when making up your mind about the type of battery you need for your application.

If you want to learn more, and if you have ample time to dive into it, check out the Battery University website.

Or, you can reach out and ask your questions to our engineering and support team. We’ll help you to design a professional battery pack, that does the job well and is also cost-efficient.