EV batteries serve as the backbone of clean energy transformation by functioning as mobile energy storage units that reduce fossil fuel dependence and enable renewable energy integration. These battery energy storage systems create distributed networks that support grid stability while driving significant carbon reduction across transportation and energy sectors.

What makes EV batteries important for achieving clean energy objectives?

Electric vehicle batteries transform transportation from a carbon-intensive sector into a clean energy asset by storing renewable electricity and reducing fossil fuel consumption. They create mobile energy storage networks that can feed power back to the grid during peak demand, supporting overall energy system stability and renewable integration goals.

The shift to electric mobility represents more than just changing how vehicles are powered. EV batteries enable a fundamental restructuring of energy systems by creating thousands of distributed storage units that can absorb excess renewable energy when the sun shines or wind blows. This capability addresses one of the biggest challenges in clean energy transition: storing intermittent renewable power for use when it’s needed most.

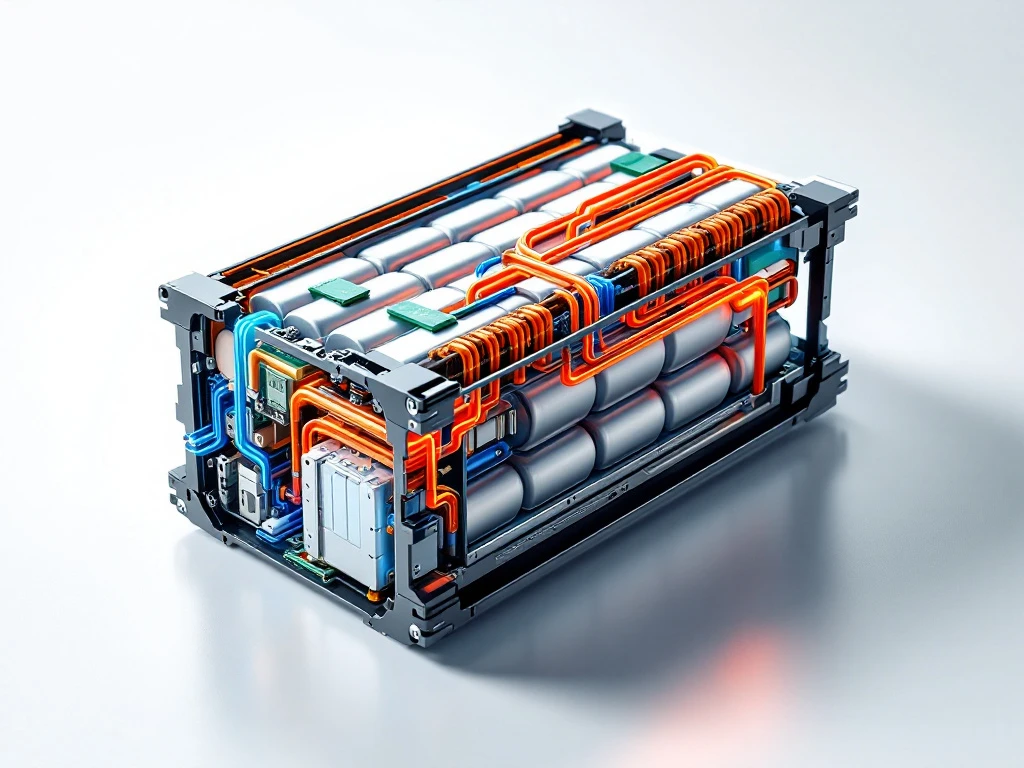

Modern battery modules are designed to handle the dual demands of vehicle operation and grid interaction. When connected to smart charging infrastructure, these systems can charge during periods of abundant renewable generation and discharge power back to homes or the grid when demand peaks. This bidirectional capability makes every electric vehicle a potential energy asset rather than just an energy consumer.

The scale of impact grows exponentially as EV adoption increases. A typical electric vehicle battery can store 50-100 kWh of energy, enough to power an average home for several days. When millions of vehicles participate in grid integration programmes, they collectively provide massive storage capacity that traditional power systems could never match economically.

How do electric vehicle batteries support renewable energy integration?

Electric vehicle batteries smooth out renewable energy intermittency by storing excess solar and wind power during peak generation periods and releasing it when renewable sources aren’t producing. Vehicle-to-grid technology allows EV batteries to act as distributed energy resources that help balance supply and demand across the electrical grid.

Renewable energy sources like solar and wind produce power when weather conditions are favourable, not necessarily when electricity demand is highest. This mismatch creates integration challenges that battery energy storage systems can solve. EV batteries connected to smart charging networks can automatically adjust their charging patterns to absorb excess renewable electricity, preventing waste and grid instability.

Peak load management becomes significantly easier with widespread EV adoption. During hot summer afternoons when air conditioning drives electricity demand to dangerous peaks, connected electric vehicles can discharge stored renewable energy back to the grid. This reduces strain on traditional power plants and helps prevent blackouts without requiring expensive infrastructure upgrades.

The buffer effect of EV batteries extends beyond daily cycles to seasonal patterns. In regions with strong seasonal renewable generation, such as areas with abundant winter wind or summer solar, electric vehicle fleets can help store energy during productive months and release it during leaner periods. This long-term storage capability supports higher renewable penetration rates than would otherwise be possible.

Smart charging systems coordinate these activities automatically, optimising when vehicles charge and discharge based on renewable availability, grid needs, and driver requirements. Vehicle owners benefit from lower electricity costs while contributing to a cleaner, more resilient energy system.

Why are EV batteries considered game-changers for carbon emission reduction?

EV batteries eliminate tailpipe emissions entirely while offering superior lifecycle carbon performance compared to combustion engines, even accounting for manufacturing impacts. As electricity grids incorporate more renewable sources, the carbon advantage of electric vehicle batteries continues to improve, creating compounding emission reductions over time.

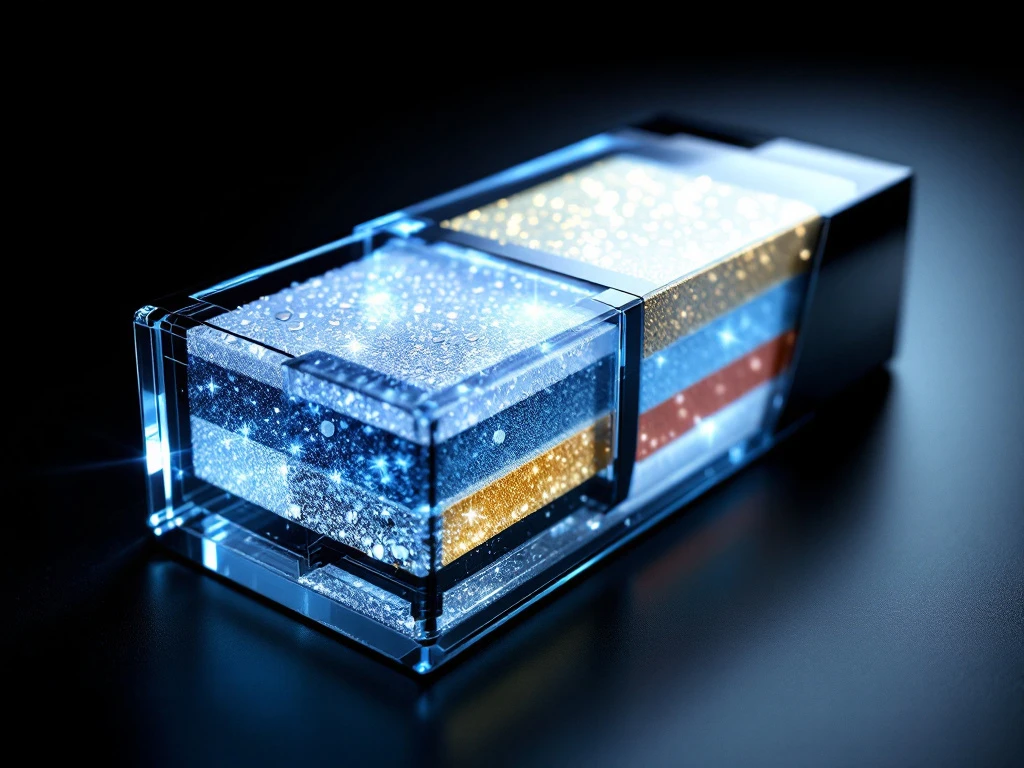

The carbon reduction potential of electric vehicle batteries extends well beyond replacing petrol and diesel fuel. Manufacturing improvements in battery production have dramatically reduced the carbon intensity of battery cell production over the past decade. Advances in recycling technology ensure that valuable materials like lithium, cobalt, and nickel can be recovered and reused, further reducing the lifecycle carbon footprint.

Quantifiable emission reductions from electric vehicle adoption vary by region based on electricity grid composition, but the trend is consistently positive. In areas with high renewable electricity penetration, electric vehicles can reduce transport emissions by 70-90% compared to equivalent combustion vehicles. Even in regions still dependent on fossil fuel electricity, EVs typically offer 30-50% emission reductions.

The carbon benefits multiply as EV batteries enable greater renewable energy integration. By providing storage and grid services, electric vehicle batteries help accelerate the retirement of fossil fuel power plants and increase the economic viability of solar and wind projects. This creates a positive feedback loop where electric mobility and clean electricity generation reinforce each other.

Battery recycling programmes ensure that end-of-life EV batteries don’t become environmental liabilities. Recovered materials can be used in new batteries or repurposed for stationary energy storage applications, extending their useful life and carbon reduction benefits well beyond their automotive service period.

What role do EV batteries play in creating sustainable transportation networks?

EV batteries enable circular economy principles in transportation by supporting material recovery, reducing urban air pollution, and creating interconnected mobility solutions that align with global sustainability commitments. Smart charging infrastructure powered by renewable energy creates transportation networks that regenerate rather than degrade environmental systems.

Sustainable transportation networks require more than just clean vehicles; they need integrated systems that optimise resource use and minimise waste. EV batteries contribute by enabling shared mobility services where vehicles can serve multiple users throughout the day, maximising utilisation rates and reducing the total number of vehicles needed.

Urban air quality improvements from electric vehicle adoption create immediate health benefits that complement long-term climate goals. Unlike combustion engines that produce harmful pollutants regardless of fuel source, electric vehicles with battery power produce zero local emissions. This is particularly valuable in dense urban areas where air pollution poses serious public health risks.

Smart charging systems create transportation networks that respond dynamically to energy availability and environmental conditions. During periods of high renewable generation, charging rates can increase to absorb excess clean electricity. When grid stress occurs, vehicles can reduce charging or even provide power back to the system, maintaining network stability without compromising mobility needs.

The interconnected nature of modern EV charging networks enables optimisation across entire transportation systems. Route planning can incorporate charging availability, energy costs, and grid conditions to minimise environmental impact while maintaining service quality. This systems-level approach to sustainable transportation wouldn’t be possible without the flexibility that battery energy storage provides.

EV batteries represent a transformative technology that makes clean energy goals achievable by creating mobile storage networks that support renewable integration while eliminating transportation emissions. The technology continues advancing rapidly, with improvements in energy density, charging speed, and lifecycle performance making electric mobility increasingly attractive. If you’re considering how battery energy storage solutions might support your organisation’s sustainability objectives, we’d be happy to discuss custom approaches that align with your specific requirements. Please contact us to explore how advanced battery systems can contribute to your clean energy transition.