When you’re pushing the limits on the track, every component of your racing machine needs to perform flawlessly under extreme conditions. This is especially true for air-cooled battery systems in high-performance applications, where temperatures soar and vibrations are relentless. Whether you’re retrofitting a sports car or building a Formula racing powerhouse, understanding the critical safety standards for these energy storage systems isn’t just about compliance—it’s about protecting your investment and ensuring peak performance when it matters most.

The unique demands of racing environments make battery safety standards absolutely essential. Unlike standard automotive applications, racing scenarios subject battery packs to extreme G-forces, rapid temperature fluctuations, and intense electrical loads that can quickly overwhelm inadequately designed systems.

1: Understanding air-cooled battery safety fundamentals

Air-cooled battery systems rely on ambient air circulation to manage thermal conditions, making them particularly suitable for racing applications where weight reduction is paramount. These systems eliminate the complexity and weight penalties associated with liquid cooling whilst providing adequate thermal management for high-performance scenarios.

The fundamental safety approach centres on preventing thermal runaway events, maintaining electrical integrity, and ensuring mechanical robustness under racing conditions. Unlike consumer applications, racing environments demand systems that can handle rapid acceleration, deceleration, and cornering forces that would challenge conventional designs.

Safety standards for air-cooled systems must account for the unique heat dissipation characteristics and potential failure modes specific to air-based cooling. This includes managing hot spots, ensuring adequate airflow distribution, and maintaining safe operating temperatures even during extended high-load periods typical in racing scenarios.

2: Thermal runaway prevention protocols

Preventing thermal runaway in air-cooled systems requires sophisticated temperature monitoring and rapid response mechanisms. Battery pack safety depends on multi-layered thermal protection that can detect temperature anomalies before they cascade into dangerous situations.

Temperature sensors must be strategically positioned throughout the battery pack, with particular attention to areas prone to heat accumulation. These sensors should trigger progressive responses: initial warnings, load reduction, and ultimately complete system shutdown if temperatures approach critical thresholds.

Thermal barriers between cell groups help contain potential thermal events whilst allowing normal airflow for cooling. These barriers must withstand the mechanical stresses of racing whilst maintaining their protective properties over extended periods of vibration and temperature cycling.

3: Airflow design and ventilation requirements

Effective airflow design is the cornerstone of successful air-cooled battery systems in racing applications. The ventilation system must provide consistent cooling even when the vehicle is stationary or moving at low speeds, conditions that can challenge natural airflow patterns.

Intake and exhaust positioning requires careful consideration of the vehicle’s aerodynamics and the racing environment. Battery cooling systems must account for potential blockages from debris, varying ambient temperatures, and the need to prevent moisture ingress whilst maintaining adequate ventilation.

Fan systems, when required, should include redundancy and fail-safe mechanisms to ensure continued operation even if primary cooling fans malfunction. The electrical load of these systems must be factored into the overall energy management strategy to avoid compromising performance.

4: Electrical isolation and insulation standards

Racing environments subject electrical systems to extreme conditions that demand robust isolation and insulation protocols. High-voltage systems require multiple layers of protection to prevent dangerous electrical faults that could endanger drivers and support personnel.

Insulation materials must maintain their properties across the wide temperature ranges encountered in racing, from cold morning practice sessions to the intense heat of competition. These materials must also resist degradation from vibration, chemical exposure, and the mechanical stresses of racing.

Safety regulations typically mandate specific clearance distances and insulation resistance values that must be maintained throughout the system’s operational life. Regular testing protocols ensure these standards remain met despite the harsh operating environment.

5: Battery management system integration

The Battery Management System (BMS) serves as the central nervous system for energy storage safety, monitoring every aspect of battery performance and health. In racing applications, the BMS must make split-second decisions whilst providing detailed telemetry for performance optimisation.

Cell balancing becomes critical in high-performance applications where uneven loads can quickly lead to cell degradation or failure. The BMS must actively manage individual cell voltages whilst maintaining overall pack performance under rapidly changing load conditions.

Emergency shutdown capabilities must be integrated with the vehicle’s safety systems, allowing for immediate disconnection in the event of an accident or system malfunction. These systems require fail-safe designs that function even when primary power or communication systems are compromised.

6: Fire suppression measures for air-cooled systems

Fire detection and suppression systems for air-cooled battery installations must account for the unique characteristics of battery fires and the racing environment. Traditional fire suppression methods may prove inadequate for lithium-ion battery fires, requiring specialised approaches.

Detection systems must differentiate between normal operational heat and dangerous thermal events. Multi-sensor approaches using temperature, smoke, and gas detection provide comprehensive monitoring whilst minimising false alarms that could interrupt racing activities.

Suppression systems should focus on cooling and containment rather than traditional fire suppression methods. Modular battery systems allow for isolation of affected sections whilst maintaining operation of unaffected areas, crucial for safely exiting the racing environment.

7: Mechanical protection and housing standards

Racing applications subject battery housings to extreme mechanical stresses that far exceed normal automotive requirements. Impact resistance must account for potential collisions, debris strikes, and the constant vibration of high-performance engines and road surfaces.

Housing materials must balance protection with weight considerations, often requiring advanced composites or specialised alloys. The structural design must maintain integrity even after minor impacts whilst allowing for thermal expansion and contraction of internal components.

Mounting systems require particular attention, as they must transfer the mechanical loads safely to the vehicle structure whilst allowing for controlled deformation in severe impact scenarios. This protects both the battery system and vehicle occupants.

8: Environmental sealing and ingress protection

Air-cooled systems face unique challenges in environmental sealing, as they must allow airflow whilst preventing ingress of moisture, dust, and debris. IP rating requirements must balance protection with cooling effectiveness.

Sealing systems must maintain their integrity across the temperature ranges and mechanical stresses encountered in racing. This includes consideration of thermal cycling effects on seals and gaskets, which can lead to premature failure if not properly specified.

Battery design standards typically require testing under conditions that simulate racing environments, including water spray, dust exposure, and pressure cycling that mimics the effects of high-speed operation.

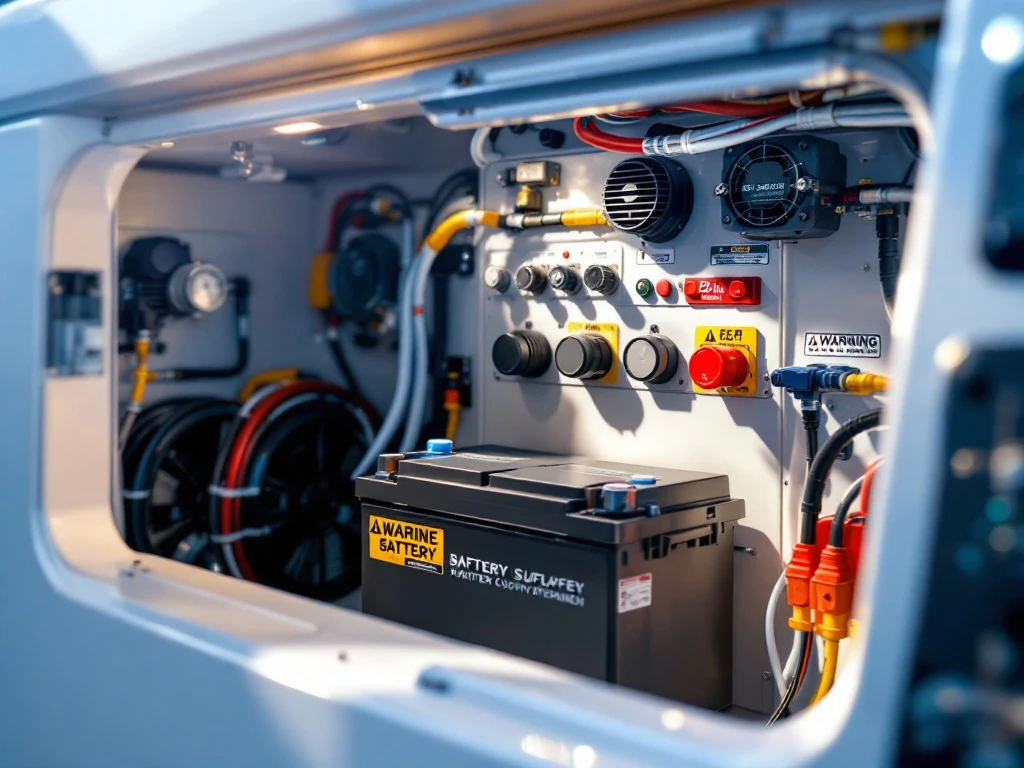

9: Emergency response and maintenance protocols

Comprehensive emergency response procedures must be established for any racing team utilising air-cooled battery systems. These protocols should address various scenarios from minor system faults to major incidents requiring immediate evacuation.

Maintenance procedures require specialised training and equipment to safely service high-voltage systems in racing environments. Personnel protection measures include appropriate personal protective equipment and isolation procedures that ensure safe working conditions.

Regular inspection schedules must account for the accelerated wear patterns typical in racing applications. This includes monitoring of connections, insulation integrity, and cooling system effectiveness to prevent failures during critical racing periods. However, many teams struggle with implementation due to common performance misconceptions that can lead to inadequate safety measures.

Building your safety-first racing advantage

Implementing these nine safety standards transforms your air-cooled battery system from a potential liability into a competitive advantage. The integration of comprehensive safety measures not only protects your team and equipment but also ensures consistent performance when victory margins are measured in milliseconds.

The investment in proper safety standards pays dividends through reduced downtime, improved reliability, and the confidence that comes from knowing your systems can handle whatever the track throws at them. As racing technology continues to evolve, these fundamental safety principles remain the foundation upon which successful high-performance battery systems are built.

Ready to elevate your racing programme with properly engineered battery safety systems? We specialise in developing custom solutions that meet the unique demands of high-performance applications. Contact us to discuss how we can help you implement these critical safety standards in your next racing project.