EV battery quality standards encompass international safety regulations, performance testing protocols, and certification requirements that ensure electric vehicle batteries meet strict safety and reliability criteria. These standards cover everything from cell design and thermal management to crash safety and manufacturing quality control. Understanding these requirements helps manufacturers deliver safe, durable battery systems for electric vehicles.

What are the primary safety standards that govern EV battery manufacturing?

International safety standards for EV battery manufacturing include UN38.3 for transport safety, IEC 62133 for cell safety requirements, and UL 2580 for electric vehicle battery systems. These standards regulate thermal runaway protection, electrical safety, mechanical integrity, and environmental performance to prevent dangerous failures.

UN38.3 focuses on transport and shipping safety, requiring batteries to withstand altitude simulation, thermal tests, vibration, shock, external short circuit, impact, and overcharge conditions. This standard ensures batteries remain safe during transportation and handling.

IEC 62133 addresses lithium-ion battery cells and batteries, covering electrical tests, mechanical tests, and environmental safety requirements. It includes overcharge protection, forced discharge testing, and thermal abuse testing to verify safe operation under various conditions.

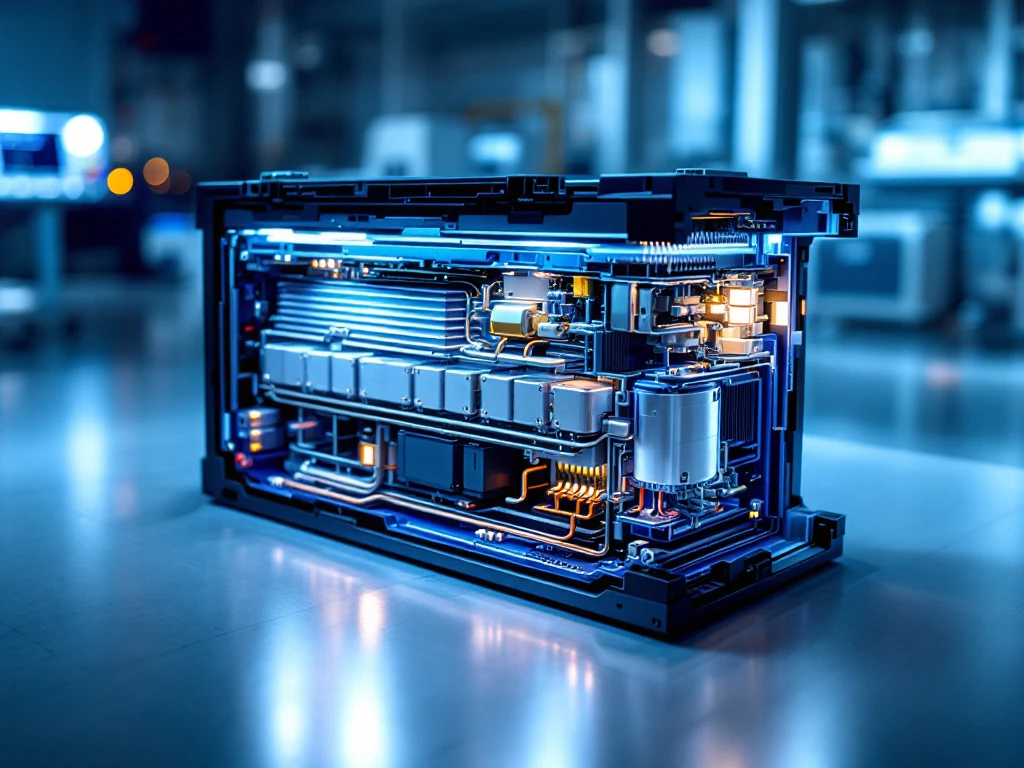

UL 2580 specifically targets electric vehicle battery systems, examining the complete battery pack including cells, modules, cooling systems, and battery management system integration. This standard evaluates crush resistance, fire exposure, seawater immersion, and electrical shock protection.

Additional regional standards like ISO 12405 for electric road vehicles and SAE J2464 for electric vehicle battery abuse testing provide complementary safety requirements. These standards work together to create comprehensive safety frameworks for automotive battery applications.

How do automotive manufacturers verify battery performance and durability?

Automotive battery testing protocols include cycle life testing, capacity retention analysis, temperature performance evaluation, and accelerated aging studies. Manufacturers typically test batteries through thousands of charge-discharge cycles while monitoring capacity degradation, internal resistance changes, and thermal behaviour patterns.

Cycle life testing involves repeatedly charging and discharging batteries under controlled conditions that simulate real-world driving patterns. This testing reveals how batteries perform over extended use and helps predict service life. Manufacturers often conduct tests at various temperatures and charge rates to understand performance boundaries.

Capacity retention testing measures how much energy storage capability batteries maintain over time. This involves periodic capacity measurements during extended testing periods, helping manufacturers establish warranty parameters and replacement schedules for vehicle applications.

Temperature performance testing evaluates battery behaviour across operating temperature ranges from -30°C to +60°C. This testing ensures batteries function safely and efficiently in various climates and driving conditions, including extreme weather scenarios.

Accelerated aging studies use elevated temperatures and stress conditions to simulate years of use in compressed timeframes. These tests help manufacturers predict long-term performance and identify potential failure modes before commercial release.

Which certifications must EV batteries obtain before market release?

Electric vehicle battery certification requirements include CE marking for European markets, FCC compliance for electromagnetic compatibility, and regional automotive certifications like ECE R100 for Europe and FMVSS 305 for North America. These certifications verify batteries meet safety, performance, and regulatory standards for commercial distribution.

CE marking demonstrates conformity with European Union safety, health, and environmental protection standards. For EV batteries, this includes compliance with the Low Voltage Directive, EMC Directive, and RoHS Directive covering hazardous substances.

ECE R100 specifically addresses electric vehicle safety requirements including electrical safety, functional safety, and protection against electric shock. This regulation covers battery system design, installation requirements, and safety measures for maintenance personnel.

FMVSS 305 provides electric vehicle safety standards for the North American market, covering electrical isolation, electrolyte spillage prevention, and post-crash electrical safety requirements. Compliance ensures batteries meet crashworthiness standards.

Additional certifications may include ISO 26262 for functional safety, particularly for battery management systems, and country-specific approvals like Japan’s JASO standards or China’s GB standards depending on target markets.

What quality control measures prevent battery failures in electric vehicles?

Battery quality standards implementation includes cell matching procedures, pack assembly validation, battery management system calibration, and comprehensive final inspection protocols. These measures ensure consistent performance, prevent early failures, and maintain safety throughout the battery system’s operational life.

Cell matching involves selecting battery cells with similar capacity, voltage, and internal resistance characteristics for each battery pack. This process prevents individual cells from becoming over-stressed during operation, which could lead to premature failure or safety issues.

Pack assembly validation includes torque verification for mechanical connections, electrical continuity testing, insulation resistance measurement, and thermal interface inspection. These checks ensure proper assembly and identify potential issues before batteries enter service.

Battery management system calibration verifies accurate voltage, current, and temperature monitoring across all cells. This includes testing protection functions like overvoltage, undervoltage, overcurrent, and overtemperature shutdowns to ensure safe operation.

Final inspection protocols encompass functional testing, safety system verification, and performance validation under various operating conditions. This comprehensive testing confirms batteries meet all specifications and safety requirements before delivery.

Manufacturing quality control also includes traceability systems that track individual cells and components throughout the production process, enabling rapid identification and resolution of any quality issues that may arise.

Understanding these quality standards helps you make informed decisions about EV battery systems for your applications. Whether you’re developing new electric vehicles or retrofitting existing equipment, working with experienced battery manufacturers ensures compliance with all relevant standards. If you need guidance on battery quality requirements for your specific application, don’t hesitate to contact our technical team for expert advice.