Elektrificatie van zwaar bouwmaterieel

Door de strenge C02-emissiemaatregelen voor bouwprojecten in Nederland (en daarbuiten) is de vraag naar elektrische versies van zwaar bouwmaterieel groter dan de huidige productie. Dit betekent dat er een groeiende markt is voor de elektrificatie van bouwmaterieel. Power Battery heeft besloten om een haalbaarheidsstudie uit te voeren om te bepalen hoe zij kunnen bijdragen aan deze trend door gestandaardiseerde oplossingen en batterijpakketten aan te bieden voor het ombouwen van voertuigen naar elektrische voertuigen met nul-emissie!

De haalbaarheidsstudie schetsen

Laurence Smits volgt een automotive afstudeerrichting aan de Fontys hogeschool, die het onderzoek uitvoert en de resultaten zal verwerken in een uitgebreid resultaat voor Power Battery. Hij zegt over dit onderzoek: “We ontdekten dat er ruwweg 40-50 verschillende typen zware voertuigen zijn die ingezet kunnen worden op een bouwplaats. Er is een grote variatie in toepassingen voor deze voertuigen, maar ze hebben ook een paar dingen gemeen, zoals hun gewicht (tot 40 ton of meer) en enorme dieseltanks (tot 1000 liter en meer).”

“Met een brandstofverbruik tot 30 l/uur kun je je voorstellen hoeveel C02-uitstoot je voor het hele bouwproject kunt verminderen als deze voertuigen allemaal EV’s zouden zijn”, voegt Laurence toe. In Nederland wordt de winst in de bouw meestal toegewezen aan het bouwbedrijf dat de beste kwaliteit voor de beste prijs kan leveren. Tegenwoordig begint de CO2-uitstoot een steeds grotere rol te spelen in de besluitvormingsprocessen van lokale overheden en bouwbedrijven. Aanbestedingen worden dus gewonnen door het bedrijf dat de laagste emissies biedt bovenop de kwaliteit van het bouwproject zelf. Dat is de basis van de business case voor de aanschaf van elektrische versies van bouwmachines.

Elektrische bouwmachines zijn nog steeds schaars

Er is een grote vraag naar elektrisch bouwmaterieel op de huidige markt, waaraan de fabrikanten van materieel niet voldoen. Dat betekent dat massa-elektrificatie van conventionele bouwvoertuigen economisch haalbaar is. Power Battery heeft met verschillende partijen in de markt gesproken en is op zoek naar langetermijnpartnerschappen met aanpassingsbedrijven, leasemaatschappijen en machinedealers door hen gestandaardiseerde oplossingen aan te bieden.

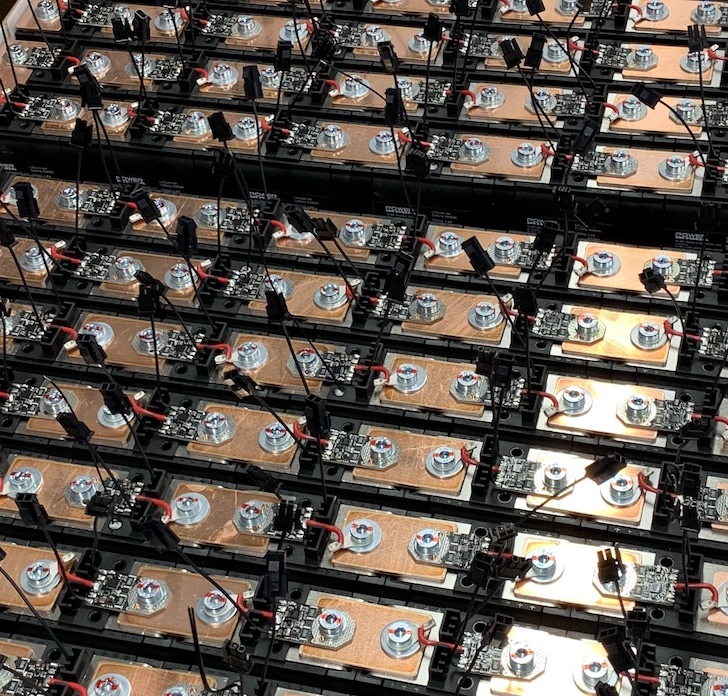

Voor ons onderzoek is de volgende stap het kiezen van één type bouwvoertuig en het ontwerpen van een professioneel, veilig en duurzaam drop-in batterijpakket, dat het brute leven op een bouwplaats kan overleven. Met dit ontwerp kunnen we deze standaardpakketten in de juiste volumes produceren. Laurence zegt: “De volgende stap in mijn onderzoek is het ontwerpen van een batterijpakket in CAD dat als standaardpakket kan worden gebruikt. Daarna bouw ik een prototype, zodat we het in een echt voertuig kunnen testen.”

Tot nu toe heeft ons onderzoek een aantal positieve resultaten laten zien en we verwachten snel naar de volgende fase te gaan. Dan kunnen we ons onderzoek afronden, waarbij we ook rekening houden met schaalbaarheid en totale eigendomskosten.

Bent u geïnteresseerd in deelname aan ons onderzoek? Dan helpt u ons te bouwen aan een groenere toekomst door bouwmachines te elektrificeren!