Vier manieren om je EV batterijpakket koel te houden

Welke koelmethoden bestaan er en wat zijn de voor- en nadelen van elke methode?

Voor de prestaties en levensduur van de batterij is het behouden van het juiste temperatuurbereik van het batterijpakket voor je elektrische voertuigessentieel. Welke koelmethoden bestaan er en wat zijn de voor- en nadelen van elke methode? We leggen het in dit artikel uit.

Luchtkoeling

Hoe werkt het?

Door lucht door het batterijpakket te laten stromen, kun je batterijen koelen. Nissan gebruikt bijvoorbeeld deze technologie om de batterijen van de Nissan Leaf te koelen. Ze laten de lucht van binnen de auto door het batterijpakket circuleren. Met dit systeem kunnen de batterijen worden gekoeld, maar ook worden verwarmd tijdens koude winterdagen.

Nadelen

Een nadeel van dit systeem is dat de temperatuur van de lucht in het voertuig ook de temperatuur is waarmee de batterijen worden gekoeld. Als je de verwarming in de auto hoger zet omdat je het koud hebt, worden de batterijen ook verwarmd. Dit is soms niet ideaal, vooral wanneer er veel vermogen wordt gevraagd.

Alternatief

Een andere manier om de batterijen met lucht te koelen, is door de buitenlucht via kanalen naar het batterijpakket in het voertuig te leiden. In dit geval zal de temperatuur van de batterijen fluctueren met de temperatuurschommelingen buiten. Tijdens hete zomerdagen zal de temperatuur van de batterijen ook stijgen. Dit is opnieuw een probleem voor toepassingen met hoog vermogen, aangezien het risico op oververhitting van de batterij toeneemt.

Wanneer geschikt?

Bij de meeste toepassingen met laag tot gemiddeld vermogen is luchtkoeling voldoende. Het gevraagde vermogen van de aandrijflijn is niet zo hoog, waardoor de batterijtemperatuur rond de omgevingstemperatuur blijft. Zelfs wanneer af en toe een hoog vermogen wordt gevraagd, zal luchtkoeling nog steeds voldoende zijn omdat de batterijen meer dan genoeg tijd hebben om af te koelen na een korte periode van hoge vermogensvraag.

Wanneer het gevraagde vermogen hoger wordt, zal het luchtkoelsysteem niet meer voldoende zijn. Laten we eens kijken naar enkele andere soorten koelsystemen.

Vloeistofkoeling

Hoe werkt het?

Vloeistofkoeling is de meest populaire manier om een batterijpakket te koelen. Een vloeistofkoelsysteem bestaat uit veel meer componenten dan bijvoorbeeld een luchtkoelsysteem. Deze componenten maken het mogelijk om de koelprestaties te verbeteren door de componenten te upgraden.

Fabrikanten van elektrische voertuigen zoals Tesla en Audi gebruiken vloeistofkoeling in hun batterijpakketten. Dit koelsysteem is een apart koelsysteem dat alleen het batterijpakket koelt. De motor en controller worden gekoeld met een tweede vloeistofkoelsysteem vanwege de temperatuurverschillen tussen de componenten. Het batterijpakket moet onder de 60 graden Celsius blijven, waardoor de temperatuur van de koelvloeistof zo laag mogelijk moet blijven. De temperatuur van de motor en controller kan oplopen tot wel 140 graden Celsius.

Wanneer deze drie componenten hetzelfde koelsysteem delen, wordt het batterijpakket verwarmd door de motor en controller. Een apart koelsysteem voor het batterijpakket is noodzakelijk.

Wanneer geschikt?

Vloeistofkoeling is de favoriete oplossing voor bijna elk batterijpakket. Of het nu gaat om een toepassing met laag of hoog vermogen, vloeistofkoeling heeft de meeste voordelen. Bij toepassingen met laag vermogen kun je het batterijpakket verzorgen zodat het altijd op de juiste temperatuur werkt. Bij toepassingen met hoog vermogen kun je het batterijpakket maximaal koelen. De temperatuur van het koelsysteem moet je zo laag mogelijk houden om maximaal vermogen voor de langst mogelijke tijd mogelijk te maken.

Naast al deze koelvoordelen kun je het batterijpakket ook verwarmen door een verwarmingselement aan het koelsysteem toe te voegen.

Zoals eerder gezegd, moeten het koelsysteem van het batterijpakket en het koelsysteem van de motor en controller gescheiden zijn. Deze twee koelsystemen kun je af en toe combineren om het batterijpakket indien nodig te verwarmen met de motor en controller. Tesla gebruikt bijvoorbeeld deze methode. Ze kunnen het batterijpakket verwarmen met de warmte die wordt gegenereerd door de motor en controller. Dit is zeer nuttig tijdens koude winterdagen.

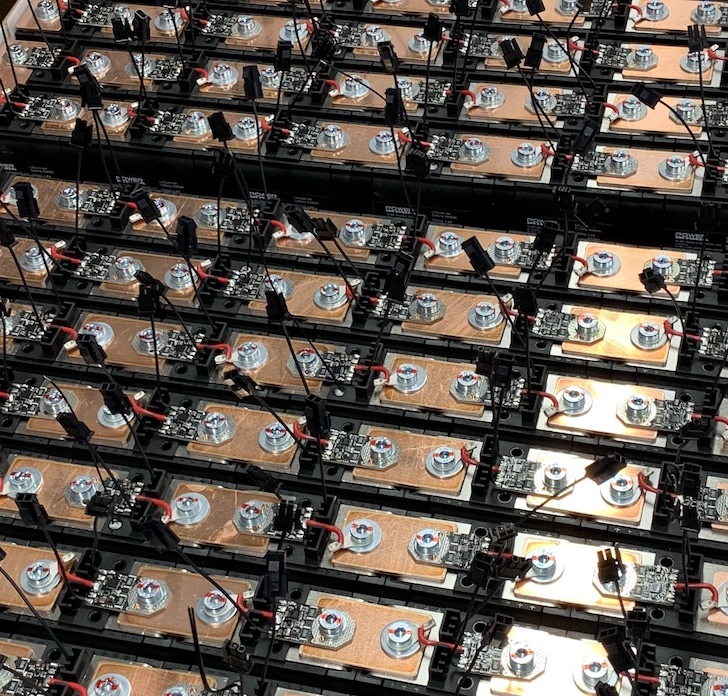

Koeling met warmtegeleidende materialen

Hoe werkt het?

Warmtegeleidende materialen, zoals heat pipes, kun je gebruiken om warmte aan het batterijpakket te onttrekken. Dit is een langzamere manier van koelen dan bij gebruik van vloeistofkoeling. Ook metalen zoals aluminium en koper zijn warmtegeleidende materialen.

Nadelen

Helaas is deze manier van koelen slechts een onderdeel van het koelsysteem in plaats van een volledig systeem. Wanneer je dit als enige koelsysteem gebruikt, moet het warmtegeleidende materiaal zeer groot zijn. Het warmtegeleidende materiaal heeft een bepaalde warmtecapaciteit. Dit is de hoeveelheid warmte die een materiaal per gewicht kan absorberen. Voor een grote onttrekking van warmte uit het batterijpakket zou het warmtegeleidende materiaal massaal moeten zijn.

Dit betekent dat je deze manier van koelen moet combineren met een ander koelsysteem, zoals de twee eerder genoemde systemen. Het warmtegeleidende materiaal zal de warmte naar het andere koelsysteem leiden.

Onderdompelingskoeling

Een andere manier om een batterijpakket met vloeistof te koelen, is door het complete batterijpakket onder te dompelen in de koelvloeistof. Deze technologie wordt al gebruikt in de wereld van supercomputers.

Nadelen

Deze methode is zeer duur. Een ander nadeel is dat de gebruikte hoeveelheid vloeistof een bepaalde warmtecapaciteit heeft. Zoals eerder uitgelegd, is dit de hoeveelheid warmte die een materiaal kan absorberen. Door het hele batterijpakket onder te dompelen in een vloeistof, kan de vloeistof slechts zoveel koelen als de warmtecapaciteit toelaat. Met andere woorden, de vloeistof warmt op samen met het batterijpakket. De vloeistof vertraagt dit proces alleen.

Wanneer geschikt?

Bij toepassingen met hoog vermogen zul je deze koelmethode moeten combineren met andere soorten koelsystemen. De behuizing kan bijvoorbeeld van aluminium worden gemaakt, dat warmte zeer goed geleidt. Wanneer lucht langs deze behuizing stroomt, kunnen het batterijpakket en de vloeistof erin worden gekoeld.

Het kiezen van de juiste koelmethode voor jouw elektrische voertuig kan behoorlijk uitdagend zijn. Bij Power Battery ontwikkelen we een unieke koelmethode voor batterijpakketten met hoog vermogen. Neem gerust contact met ons op als je vragen hebt over jouw project, of vraag een consult aan.

Advies op maat voor jouw EV-project

Het kiezen van de juiste koelmethode voor jouw elektrische voertuig kan behoorlijk uitdagend zijn. Bij Power Battery ontwikkelen we een unieke koelmethode voor batterijpakketten met hoog vermogen.

Neem gerust contact met ons op als je vragen hebt over jouw project, of vraag een consult aan.